SpecGAGE3D

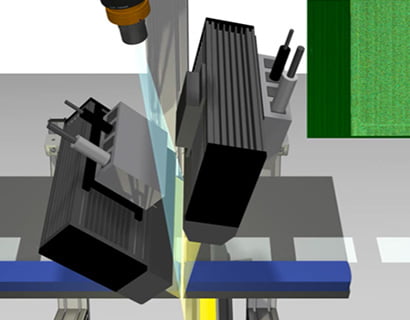

Automatic surface inspection of highly reflective objects

-

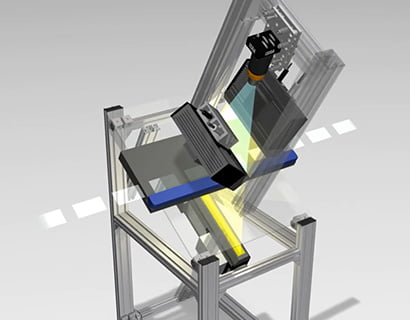

Automatic defect detection and shape inspection for reflective surfaces

-

Determination of stable and comparable values

-

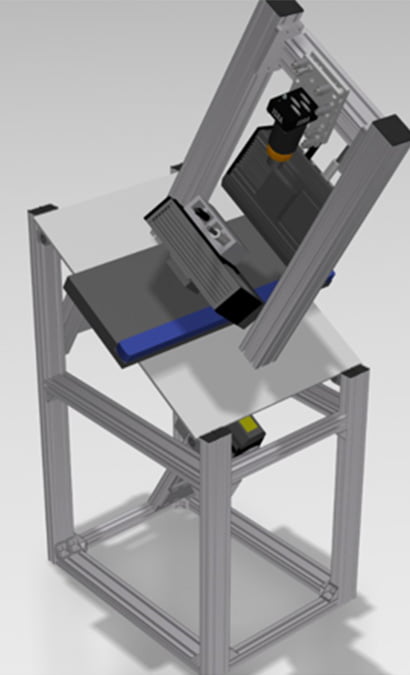

Multi-part and large-part measurement approach

-

Global form and defect control in one system

-

Real-time production monitoring & process control

Automatic surface inspection of highly reflective objects

SpecGAGE3D sets the standard for quality control of reflective surfaces such as automotive interior/exterior, displays, mirrors, wafers, and mobile devices. Using deflectometry, it detects shape deviations and surface defects in a single measurement and compares the data to CAD to evaluate differences in seconds. SpecGAGE3D accurately identifies surface defects and ensures objects meet required specifications, streamlining the inspection process for maximum efficiency.